24 hours

|

|

||

| Detail | ||

|

1.System Introduction The transformation of modern manufacturing industry calls for increasingly higher requirements for pump/valve product quality, therefore the pump/valve test devices are becoming essential core equipments of related production, R&D, energy saving and quality control sectors. Upgraded according to the latest industry trends, the Pump/Valve Integrated Test System S4.0 has “one-full and three-high” characteristics of full functions, high precision, high degree of operating automation and high operating reliability. At the same time, compared with the traditional pump/valve testing systems, the system has modern integrated design, standardized components / module, as well as non-standard customized overall system design. 2.System Characteristics 2.1.Modern Integrated Design a)By adopting modularization design, the system eliminates a large number of secondary instruments and buttons employed by the traditional central control room. All the data are acquired and controlled through the central controller, achieving "one-click" operation on the computer. b)The upgraded operation table is grand, beautiful, intelligent and simplified, providing customized 3D visual operation, real-time video surveillance and voice intercom. c)The upgraded pump/valve integrated test system has refined and perfect interface, presenting bilingual illustrations and reports, and has the functions of system user management and record, real-time data and curve display, operating tips and help, as well as data monitoring and alarming, etc. 2.2.Full Functions,High Precision, High Degree of Operating Automation and High Operating Reliability a)Based on the torque method, simplified electrometric method and electrical loss analysis method, the upgraded test system can achieve type tests and release tests for various types and specifications of pumps, and flow characteristics, flow resistance characteristics test for universal valves. The system meets the following criteria for the highest accuracy requirements: BS EN ISO 9906 Roto-dynamic pumps —Hydraulic performance acceptance tests — Grades 1,2 and 3 GB/T 3216 Roto-dynamic pumps—Hydraulic peformance acceptance tests GB/T 12785 Test methods for submersible motor-pumps GB/T 7784 Test methods for power reciprocating pumps GB/T 9064 Test methods for screw pumps GB6245 Fire Pump GB/T 16750 Electrical submersible pumps BS EN 1267 Valves Test of flow resistance using water as a test fluid GB/T 30832 Valves Test method of flow coefficient and flow resistance coefficient JB/T 5296 Universal Valves Test method of flow coefficient and flow resistance coefficient b)The high precision sensors of international famous brands or domestic first-line brands are adopted for the upgraded test system. General configurations of sensor accuracy are as following: flow (imported: 0.2%; domestic: 0.5%), head: 0.2%, torque: 0.2%, speed (conventional pumps: ±1RPM, shielding pumps and submersible pumps, etc: 0.1%), voltage / current: 0.2%, motor power: 0.5%. Moreover, the system can measure electrical parameters with high precision and analyze power quality under disturbance environment such as harmonic interference of high power frequency converter. Measurement accuracy of electrical parameters: voltage / current: 0.1%, motor power: 0.2%. c)The industrial-level site monitoring is realized based on SIEMENS PLC. The data are acquired and processed in a high-precision, high anti-interference and high-reliable way based on SIEMENS data acquisition module. The upgraded test system meets both the industrial-level requirement of stability and reliability, as well as laboratory-level requirement of high precision and high standard. 2.3.Standardized Components / Module International and domestic standardized products are adopted for all monitoring and data acquisition equipment, which could be purchased and replaced directly if there is a failure after the expiry of warranty. Meanwhile, the system is designed through standard signal channel, allowing hardware customization for upper computer software, thus the replaced standardized equipment can achieve seamless integration with the original system for higher maintainability. 2.4.Non-standard Customization ofSystem Design Our main professionals are masters from Fluid Machinery Laboratory, Chemical Machine Institute of Zhejiang University, possessing rich knowledge of fluid mechanics as well as rich pump/valve test system design experiences. Furthermore, our company has numerous successful cases of implementation, including design, installation and commissioning services of various pump test systems for well-known foreign pump enterprises, domestic first-line pump/valve enterprises and famous universities and research institutes. We can meet the needs of different customers' personalized customization. 3.System Display

Pic.1 Pump Integrated Test System

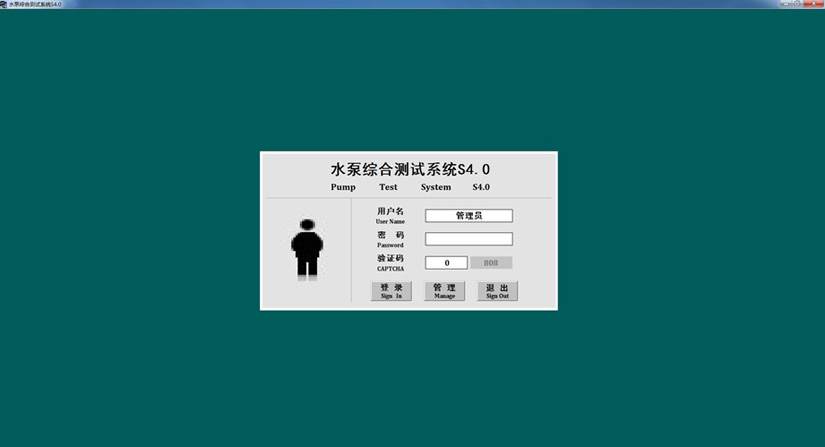

Pic.2 System Software Login Interface

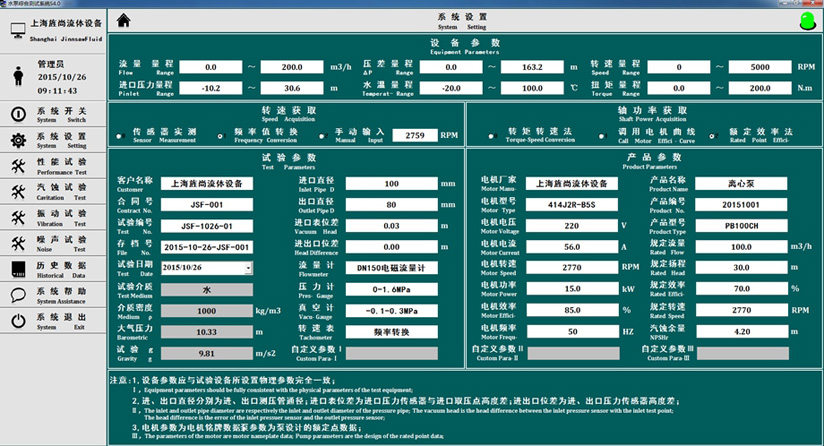

Pic.3 System Software Setting Interface

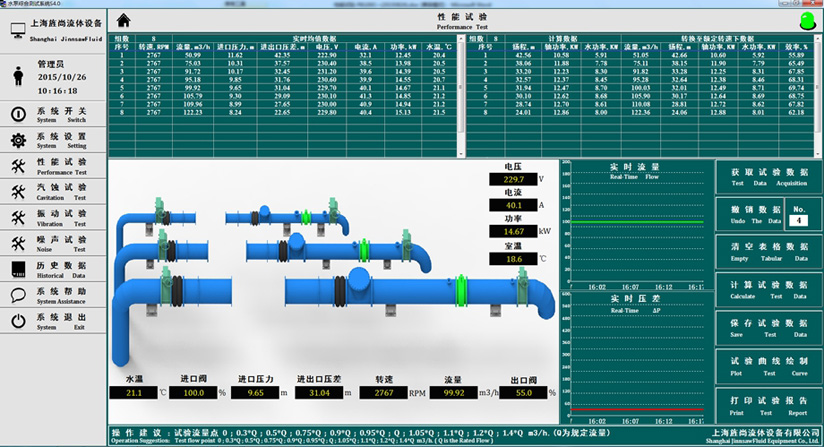

Pic.4 System Software Performance Test Interface

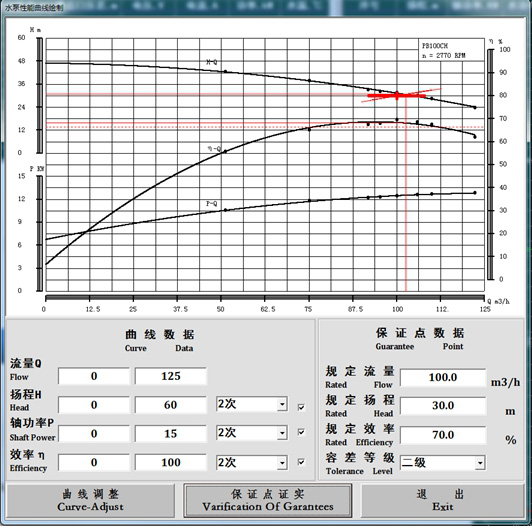

Pic.5 System Software Performance Curve Drawing Interface

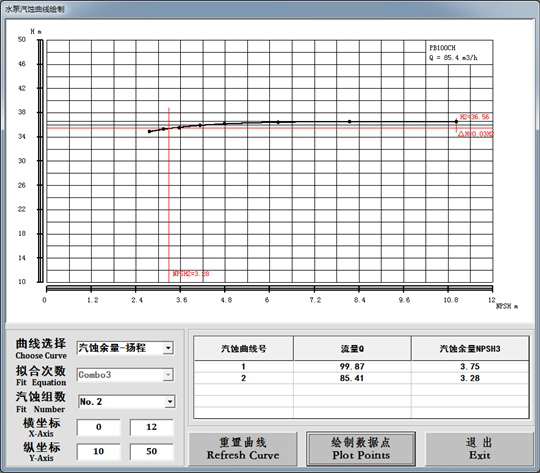

Pic.6 System Software Cavitation Curve Drawing Interface

Pic.7 System Software Historical Data Query Interface

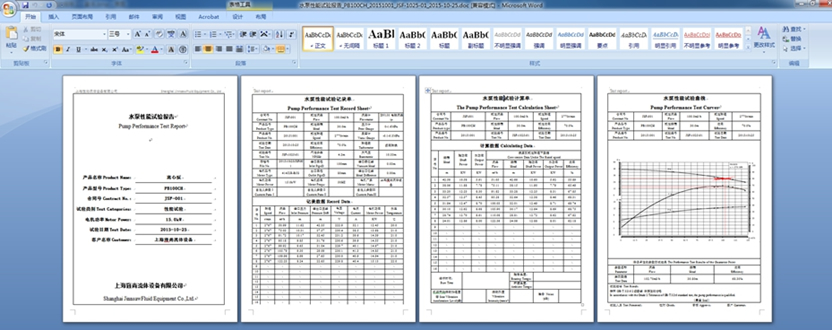

Pic.8 System Software Test Report Sample

|

||